COMPANY INFO

PROGRAM

TERMS & CONDITIONS

Quality Control

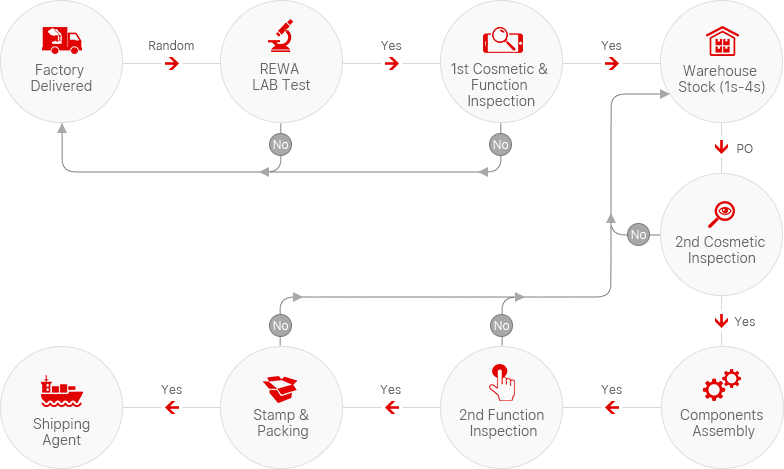

As one of the most professional electronics aftermarket solution providers in wireless repair industry, REWA has been dedicating itself to benchmarking the industry quality control. Every screen from REWA is 100% strictly tested by our specialized QC team. This is our promise for customers and we are confident with our products, because we take "Quality Above All" as our producing and testing principle all the time.

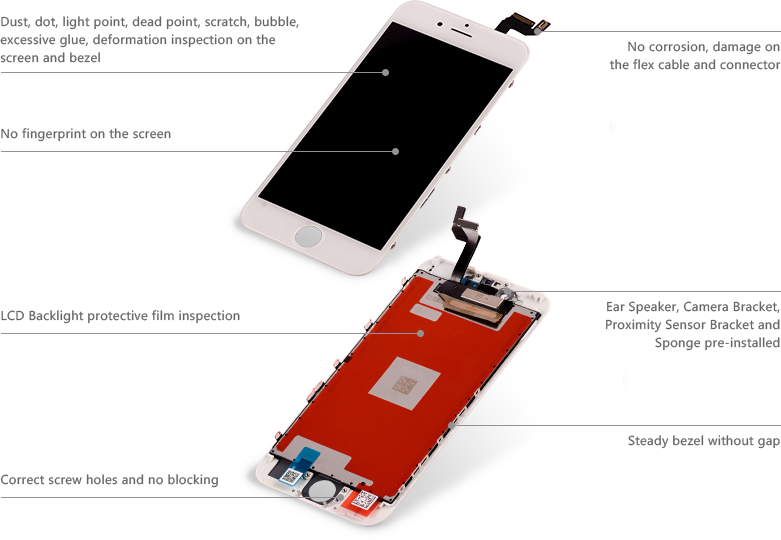

STRICT QUALITY CONTROL STANDARD

5 Quality Classification

OEM NEW

Original and New from OEM factory.

OEM USED

Original but Used already, torn down from used/new devices..

OEM REFURB

Refurbished New from Original Used parts by replacing, cleaning, oxidation, polishing, etc. procedures.

S+ GRADE

Original materials and assembled by 3rd-Party factory.

A+ GRADE

Compatible materials and assembled by 3rd-Party factory.

CERTIFIED PRODUCTS COME FROM STRICT QUALITY CONTROL PROCESS

LCD SCREEN INSPECTION & TESTING DEMO

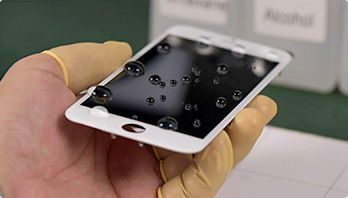

- ① Cosmetic Inspection

- ● Check whether the surface of glass lens damaged or off paint,etc.

- ● Check whether front bezel debonding, damaged, screw hole blocked, etc.

- ● Check whether flex cable broken or damaged.

- ● Check whether backlight adhesion normal or not.

- ● Check hydrophobic effect with water, alcohol, and N-hexane.

- ② Function&Display Test

- ● Test touch function by pulling up and down, switching page, moving icons.

- ● Test 3D Touch function and sensitivity.

- ● Check whether the pure color screens normal or not.

- ● Check whether the screen turns black under polarizer.

- ● Test Color Coordinates & Brightness with Color Analyzer CA310.

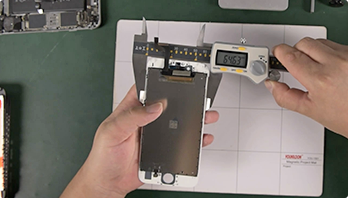

- ③ Structure Test

- ● Measure thickness, width and length.

- ● Check whether LCD metal plate well matched or screw hole well aligned.

- ● Check screen fitness with iPhone housing after installation.

- ● Check whether function normal or not after installation.

- ● Check whether light leaked or backlight conflicted with LCD Touch ID function test.

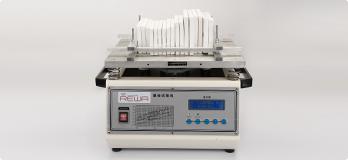

- ④ Vibration Test

- ● Electromagnetic Vibration Test (Amplitude: 2mm, Frequency: 50HZ, Time:1H).

- ⑤ Aging Test

- ● Dynamic Test (condition: +45℃; play video for 2Hrs ).

- ● Static Cycle Test (condition: -20℃/2Hrs, +55℃55%RH/2Hrs, +55℃/4Hrs).

Other Parts

Other Parts